In Stock and Custom Order Handpans for sale

Hand Pan Shell Forming Methods

The handpan art form has been developing exponentially quicker as more and more people are starting to explore building these types of drums. This is leading to novel building ideas being released to the public almost weekly. One topic of development has been basic shell forming. Whereas the steel pan has been traditionally hammered or “sank”, the birth of the handpan arrived on deep drawn shells fabricated by Panart. Years later, Jim Dusin and Kyle Cox of Pantheon Steel developed a new forming process called “Rolling”. While it is similar to traditional metal spinning (that some handpan builders have also used), there are fundamental differences in the Rotations Per Minute as well as how the shell is held and formed. In 2015, the deep drawn shell became increasingly popular after Shellopan lead a cooperative project to produce the shells and sell them to dozens of other builders. Now additional builders such as Ayasa also offer deep drawn shells. In 2016, Colin Foulke popularized another traditional metal forming process called hydro forming. Numerous more builders began using the method after Colin shared his Machinery Design. The only other method that we have heard of that we have not seen used is “Single Point Incremental Forming”, which is referred to by Soren Maloney in at least one of his Academic Papers (note that the paper will immediately begin downloading to your computer when you click on the link).

At Saraz, we have explored a few of these methods. While we have mostly built fully hammer shaped instruments, we were one of the first builders beyond Pantheon Steel to explore the Rolled Shell. Here is a video of a Rolled Shell Saraz built in 2016.

Once Shellopan began offering deep drawn shells, we also explored some of those. The following video is a Saraz built on a Shellopan shell:

We have also explored a couple deep drawn shells from Isthmus Instruments. Here is a video of a Saraz built from one of those shells:

We have also built a Saraz from a Hydro Formed shell fabricated by Bill Roberts in Florida. The following video is of the only Saraz built on a Hydro Formed Shell.

Why Fully Hammer Shaped Saraz Handpans?

With so many potential building methods, we are sometimes asked “Why do we choose to continue focusing on fully hammer shaped shells?”

6 reasons why we focus on hammer shaped shells

1. Because we have a team to share the workload

While we have found that sinking shells is one of the easier skills to learn in the process of building a handpan drum, our method has required at least 20-30 shells to get good at sinking a shell smoothly and most importantly with an ideal stretch (with an experienced teacher). Figuring out on our own how to sink an ideal shell for our process and preferences took us at least 200-300 shells. While it is much easier using a pneumatic hammer than hammering a shell entirely by hand, it is still a physically intensive job, especially compared to pushing a button on a machine that does it for you. With a focus on shell independence and an appreciation for the tone and timbre of hammer sunk shells, Mark has rarely considered trying to entirely bypass sinking shells by hammer. His interest in using other materials has primarily come from a curiosity to learn more about the handpan building process and the nature of tuned steel by trying new methods. For this reason mainly, he developed a team of people to contribute to the workload necessary for building and developing the Saraz. In the 4 years that the Saraz has been in production, 7 people have been trained to sink shells. While the process evolved in different directions through the hard earned lessons of a couple people, Mark’s father, Papa Steve, deserves most of the credit for developing the current shell sinking process at Saraz. It is important to realize that had Mark been building the Saraz alone for the last 4 years, it would not have evolved in the way it has and he would definitely not be using hammer shaped shells as the process would have been simply too brutal for him to do in addition to shaping dimples, forming ports, and tuning.

While we CAN sink shells as a team, there are other more important reasons that we CHOOSE to still focus on hammer sunk shells. The main reasons are because of the nature of the material as well as its tone and timbre.

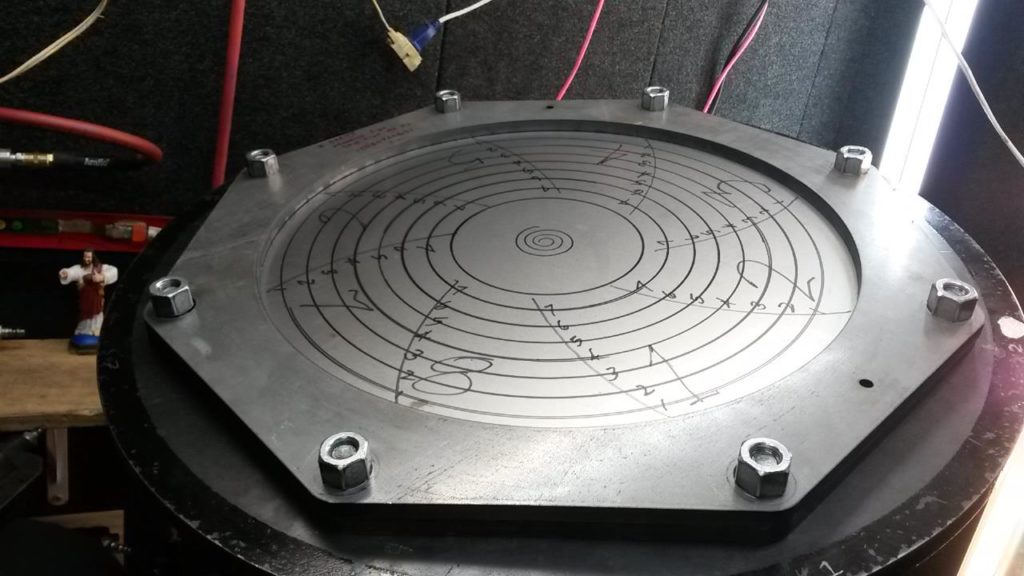

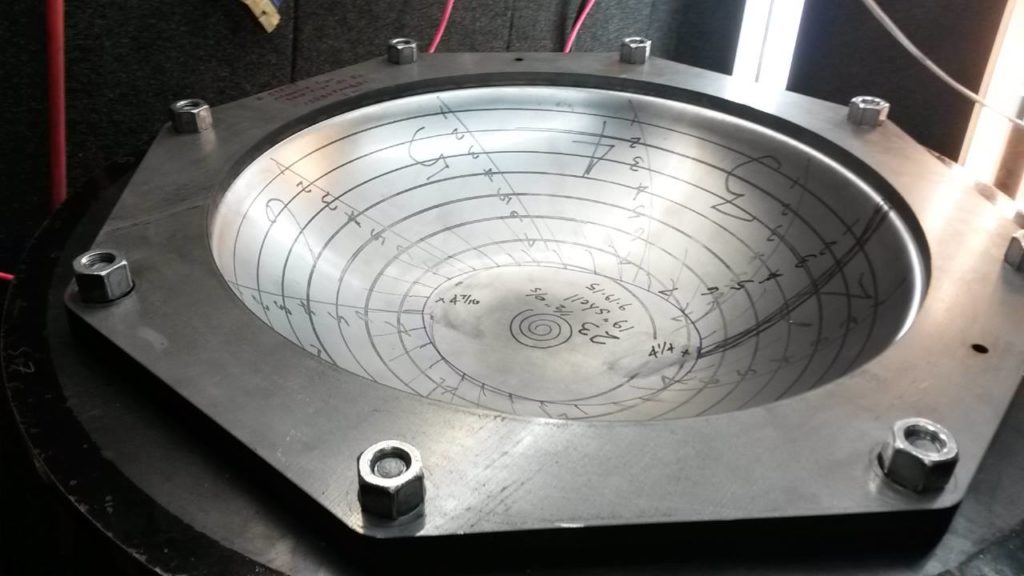

2. Shell Thickness Profile

We have developed a process that leads toward a thickness profile which we prefer as well as note architecture based around this thickness profile. The center of a Saraz shell receives the least hammer strikes in order to keep it as thick as possible while most of the stretch is in a ring around the center note. This area is approximately between 5 inches/12 cm from the center point of the shell and 4 inches/ 10 cm from the rim. Near the rim on a hammered Saraz shell is the thickest while the next thickest place is the center of the shell.

Tuned steel notes are similar in many ways to tuned strings. Lower notes want thicker strings to vibrate appropriately while higher notes want thinner strings to vibrate appropriately. Consider the thickness of different guitar strings as an example. Panyard, one of the finest steel pan builders in the world, grinds down the thickness of every note on their instruments to their ideal thickness for this reason.

Relative to other forming methods, we have found that the center of our hammer shaped shells is a similar thickness to that of the rolled shells that Pantheon once sold, which were formed on the same thickness of metal (approximately 1.2 mm thick). The center of a Hammered Saraz shell is thicker however than the center of a 1 mm Shellopan deep drawn shell. The center of a hammered Saraz shells is also thicker than the hydro formed shells that we have seen formed from 1.2 mm thick steel. With the traditional layout of a handpan having the lowest note in the center, this is very important! Compare this to a traditional steel pan where the lowest notes are typically near the rim while the highest notes are in the center.

Our hammer sunk shells are also slightly thinner in the ring of primary stretch than a deep drawn shell and much thinner than some of same area on the hydro formed shells that we have seen, however our hammer sunk shells are thicker than the same areas on a rolled shell. Each of these deviations leads toward a desire for different ideal note size. For example, the note form that we use for E4 on a hammer shaped shell is one note larger than the note form that we use for E4 on a rolled shell. This is because thicker metal seems to inherently lead toward bigger notes while thinner metal inherently leads toward smaller notes. While there are some ways to compensate for this, we are speaking about generalized inherent nature. Because of the thickness profile, fully hammer shaped center notes on a Saraz tend to be stronger and stiffer than on a deep drawn Saraz, which are very easily bendable. The highest harmonic partials such as G#6 or A6 (the compound 5ths of C#5 and D5) are a bit easier to make sing on hammer shaped Saraz than on deep drawn Saraz while they are the easiest to make sing on a rolled shell Saraz. This is not to say that beautiful instruments can not be made on shells from other forming methods as multiple builders have achieved it on each forming method. It is only to explain how and why we have designed our architecture around the hammered shell method.

3. Tone and Timbre

Another reason that we prefer hammer shaped shells is because of the inherent nature of the tone and timbre. While much of this equation is enormously influenced by heat treating, metal alloy, and especially architecture, there are inherent qualities to the hammer sunk shell that appear somewhat universal. Particularly, hammered shells appear to have a nice and balanced degree of coupling or note activation, at least for our particular taste as players. It is very common for lower notes to activate higher notes. For example, a B3 might activate a B4 on the other side of the instrument because they share the same frequency (B4). Sometimes, a high note might also activate a lower note in the same way. Controlling the degree of this coupling is the only reason why we turn some notes more parallel to the rim (particularly notes that share the same frequencies as the center note). In comparison, there is much less coupling on a deep drawn Saraz or on the hydro formed instruments that we have seen.

We would never proclaim that either shell or quality is better or worse. It is simply a matter of preference and personal taste. Some players and builders prefer less activation while we prefer a bit more. There is a limit however to how much we prefer. When we were building predominantly rolled shell Saraz, our architecture and building process of the time lead to much greater coupling to a point that we sometimes did not prefer. While the Halo has developed in ways that tame this variable considerably resulting in a beautiful balanced instrument, there seems to be an inherent quality of strong coupling with the rolled forming process. We particularly found this to be true with bottom notes on rolled shells.

4. Note Isolation

Another interesting quality of comparison between forming methods is note isolation. While we prefer just the right amount of coupling, we also want the best note isolation possible between adjacent notes. While it is nice to have 10, 11, or even 12 notes on a top shell, it becomes increasingly more difficult to achieve excellent isolation with every instrument. This is what is most impressive in the instruments of builders that have achieved it! Of the forming processes that we have explored, we have found that the hammered shell has the most inherent isolation for our building methods and architecture. While of course great isolation can be achieved on a rolled shell (as Pantheon Steel and Symphonic Steel have shown countless times) and on a deep drawn shell (as Echo Sound Sculptures has shown countless time), we have found that with our own hammer shaped instruments, it is slightly more consistent and easier to achieve than on our rolled and deep drawn instruments.

5. Sustain and Brightness

Two other qualities worth mentioning are sustain and brightness. Again these are very strongly influenced by the alloy, heat treatment and note architecture, however we find there is a bit more inherent sustain as well as brightness on a hammered shell than on a deep drawn or most of the hydro formed instruments that we have heard (with the recent Halo as an exception). On the other hand, there is less inherent sustain and brightness on a hammered shell than on a rolled shell. While the brightness of high frequency amplitude can be strongly influenced by stress relieving a hammered shell, we have found it a bit more difficult to increase on the more “ceramic” nature of the deep drawn shells without compensating some of the rust resistance. Conversely, we have found that the same quality can be difficult to harness and control with our building methods on a rolled shell without addressing the issue through architecture or heat treatment.

6. Note Stability

A more recent discovery that we are honestly very surprised by is the note stability of our hammered shells relative to our other instruments or anyone else’s. In all honestly, we are absolutely shocked by it actually! After building instruments since 2012, we have now seen many of our instruments age as well as our friends instruments age as we have performed tune ups and repairs. First we will say that our rolled and deep drawn Saraz are at least as stable as other builders instruments crafted on the same shell. All of those instruments tend to drift about 5-8 cents per year (typically sharp) with normal playing, hence the wide spread recommendation to get a tune up every 1-3 years.

We have been continually surprised in 2017 and 2018 to revisit some damaged hammer sunk Saraz that have come back for repair after minor bangs and drops. Typically the damaged note is has been out 50-150 cents from the damage. Maybe another note or 2 is out 10-15 cents, also likely from the damage. What has been surprising is that the rest of the notes have been exactly how we left them 12, 18 or even 24 months before. Feeling shocked, we have written more than one of these customers to ask if anyone else has tuned the instrument only to discover that no one has other than us. After seeing a number of our 2015 instruments and later for tuning check ups, we have found that the average rate of drift on a fully hammer shaped Saraz built in 2015 or later is about 1-2 cents per year even on instruments played very regularly by some what mildly aggressive players.

While much of our note stability is due to our shaping and tuning process, which is focused greatly on stability and balancing the tensions between notes and interstitial areas in order to minimize longer term stress relief of the internal tensions, we have discovered that our hammered shells are at least twice as stable as other Saraz built on deep drawn or rolled shells that have been put through the exact same building and tuning process. What this means is that our hammered shells appear to drift maybe 1-2 cents per year instead 5-8 cents like most handpans. While this is seriously splitting hairs and we still have a lot more data to collect on the topic, we are gathering growing evidence that our hammered shell is currently the most stable handpan shells we have worked with yet.

In summary

We would like to clarify that we do not feel that a hammer shaped shell is the best or even better than other shells or anyone else’s process. We know builders that have made some of the highest quality handpans in the world on rolled and deep drawn shells.

The intention of these explanations are to elaborate on why WE currently prefer to focus on the hammered shell as builders and as players. Not everyone feels the same about these qualities as we do. Everyone’s building process is at least a little different, which leads to different inherent qualities. We feel that this is great because it leads to a diversity of tones, timbres and instruments in the world. This diversity of preference also leads some builders toward “thinking outside of the box” and exploring completely new ideas. When is someone going to use a “Single Point Incremental Formed” shell to build a handpan? How about it Soren? We would love to explore one if we had the opportunity because with each different material and forming method, we learn something new about the nature of vibrating tuned steel membranes.

In a time when a recent and growing majority of builders are utilizing deep drawn and hydro formed shells, one main reason that the Saraz sounds unique among the art form is because of the primary shaping process. We will however continue to explore and build instruments on different materials. We still have some rolled shells as well as deep drawn shells from both mentioned fabricators in our stock that will one day become Saraz. We also look greatly forward to the next step of exploration and development in this young art form as it will inevitably reveal new secrets about the internal structure of vibrating tuned steel membranes.

With much respect to all builders,

-The Saraz Crew